Most operators deal with Corrosion Under Insulation (CUI) across the world. In some cases, in order to preserve the process conditions the pipe must be insulated. This insulation, at a specific temperature range while using carbon steel for the pipe, produces moisture. These conditions, as well as other factors, can produce external corrosion, called Corrosion Under Insulation (CUI). Left to its own devices, CUI can cause serious problems and even catastrophic consequences.

The US Chemical Safety Board issued a report in 2008 stating “The highest incidence of reported leaks in refining and chemical industries are due to CUI and not to internal process corrosion.” CUI is being recognized in the industry as a unique damage mechanism (API RP 583).

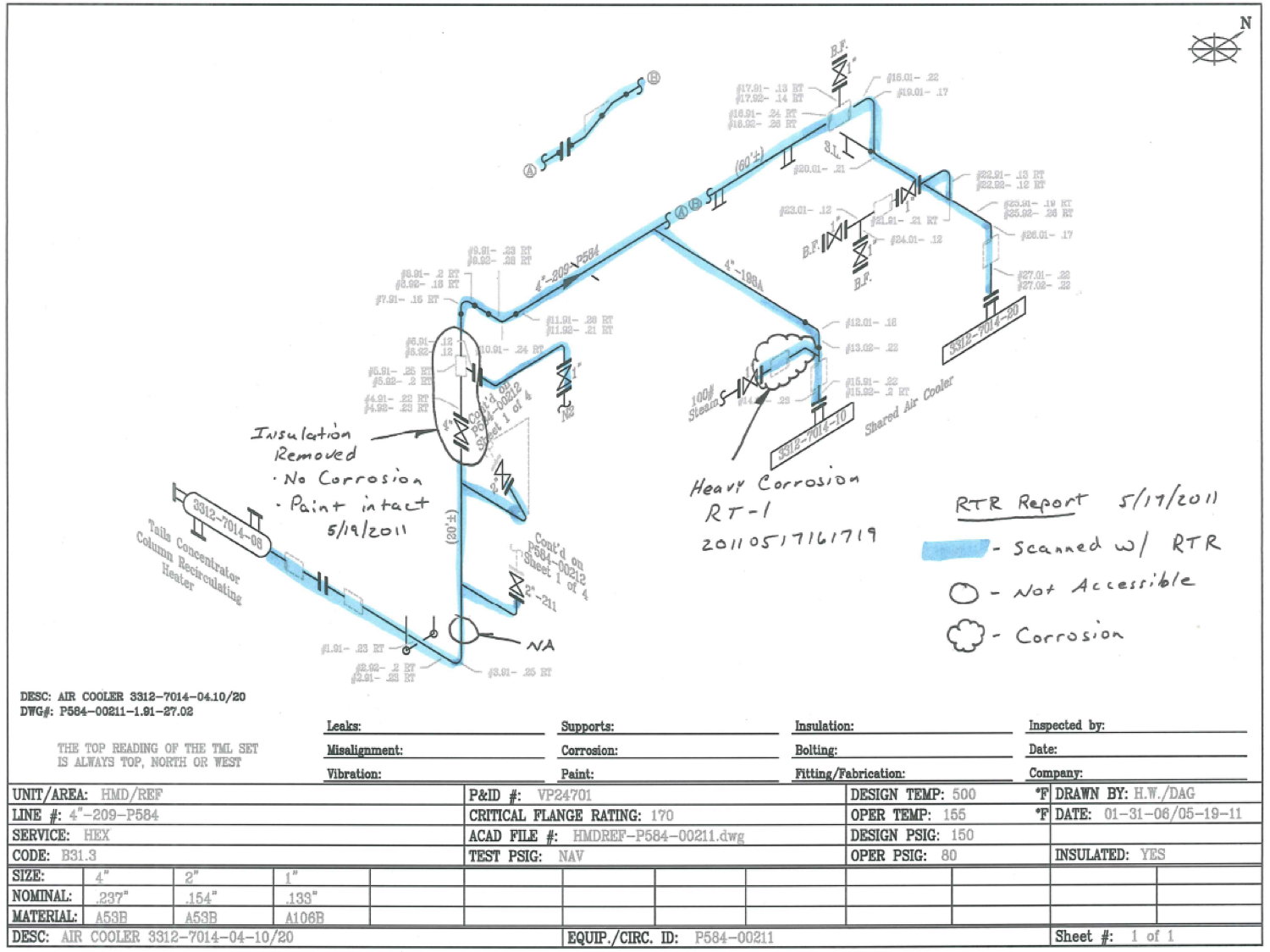

This hidden enemy provides a challenge to the Inspection, Reliability, and Maintenance departments. Due to the unpredictable nature of CUI, identifying, tracking, and mitigating CUI across assets can have many barriers. The work process is typically addresses with API 510 and 570 Visual Inspectors that are technically proficient in identifying the “tell tale” evidence of CUI, simultaneously checking and identifying external location categories where moisture is trapped under insulation.

Unless the operator completely coats the carbon steel, it is likely CUI can never be completely mitigated. The challenges consist in three primary areas.

There’s no substitute for qualified personnel, procedures, and a management process to put together a good CUI program, but these alone will not address the problem statement.

A digital solution must be put in place to perform the assessment for CUI, identify mitigating actions (current, follow-up, and future), understand process and physical changes, in an effort to communicate to all stakeholders who are address Loss of Containment (LoC) due to CUI.

There are two software solutions on the market today that addresses this need. They are:

or

A sustainable CUI program over a 5, 10, 15 year period. Communicating critical information to all key stakeholders to identify, mitigate, and avoid a Loss of Containment due to CUI.

A Higher Form of

Asset Intelligence

AsInt brings a fresh take on the design of mechanical integrity and reliability software with faster, more intuitive functionality for the multi-device generation.

© Copyright 2024, All Rights Reserved by AsInt, Inc.